OsecoElfab’s FAS Rupture Disc

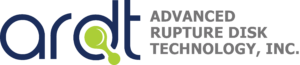

The OsecoElfab FAS™ is a high performance forward acting rupture disc designed and manufactured for high-performance and demanding rupture disc applications. The FAS features the lowest KR in the industry for a forward acting disc. The FAS™ rupture disc is designed and manufactured for high-performance and demanding rupture disc applications. The disc is cross-scored after the forming of its high crown. This process yields a high-performance disc to withstand high operating pressures within the most difficult applications. The FAS offers a smooth non-scored surface on the process side. This limits product accumulation on the disc and reduces the risk of polymerization and crystallization of media on the disc surface. The low KR value and high combination capacity factor make the FAS is an excellent choice for isolation of safety relief valves.

- The FAS is available in line sizes ranging from 1 inch diameter all the way up to 24 inches diameter.

- The FAS is available in burst pressures ranging from 40 psig all the way up to 5000 psig.

- The FAS is available in burst temperatures ranging from cryogenic temperatures all the way up to 900 degrees F.

- The FAS is available in all OE standard materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276). Other materials may be available or offered on request.

- The FAS works well in gas or vapor services, as well as liquid or two-phase services. The FAS works particularly well in sticky or fouling services.

- The Kr value for the FAS, when opened by vapors or gases is Krg = 0.223, and when opened by liquids or slurries is Krl = 0.19.

- The FAS has a 90% operating ratio, meaning the FAS operates reliably and with a long service life at pressures up to 90% of the marked burst pressure. Pressure excursions above this 90% operating ratio will shorten the lifespan of the FAS.

- The FAS is only offered with a 0% Manufacturing Design Range (MDR), meaning there will never be any variation between what burst pressure you order, and what burst pressure is marked on the tag of the rupture disk.

- The FAS is only offered with ASME-specified burst tolerances of +/- 5% of marked burst pressure for burst pressures above 40 psig, or +/- 2 psig for burst pressures at or below 40 psig.

- The FAS is a scored metal rupture disk, in a non-fragmenting design, meaning the FAS can be installed upstream from a pressure relief valve.

- The FAS does not have a vacuum support. The FAS is designed to handle vacuum service, but only when the disk material is thick enough. This means that FAS disks with low burst pressures cannot withstand full vacuum.

- The FAS is a forward acting metal rupture disk. Process pressure is applied to the concave side of the rupture disk. Increasing process pressure stretches the rupture disk until the metal yields and tears open along the scored lines.

- The FAS, like all for forward acting metal rupture disks, does best in static pressure applications. The FAS handles pressure cyclic services fairly well, but reverse acting metal rupture disks are typically recommended, to ensure the tag stays attached to the disk for services with oscillating pressures.

- The FAS is offered at lower set pressures with a stiffening ring, to better keep the tag of the rupture disk attached. This configuration is called the RFAS.

- The FAS is offered with a PFA liner or shield on the inlet side of the rupture disk, to enhance corrosion protection, or to enable better sealing of high pressure, thick FAS disks within the holder. This configuration is called the FASL

- The FAS is designed, manufactured, and certified to ASME BPVC Section XIII requirements.

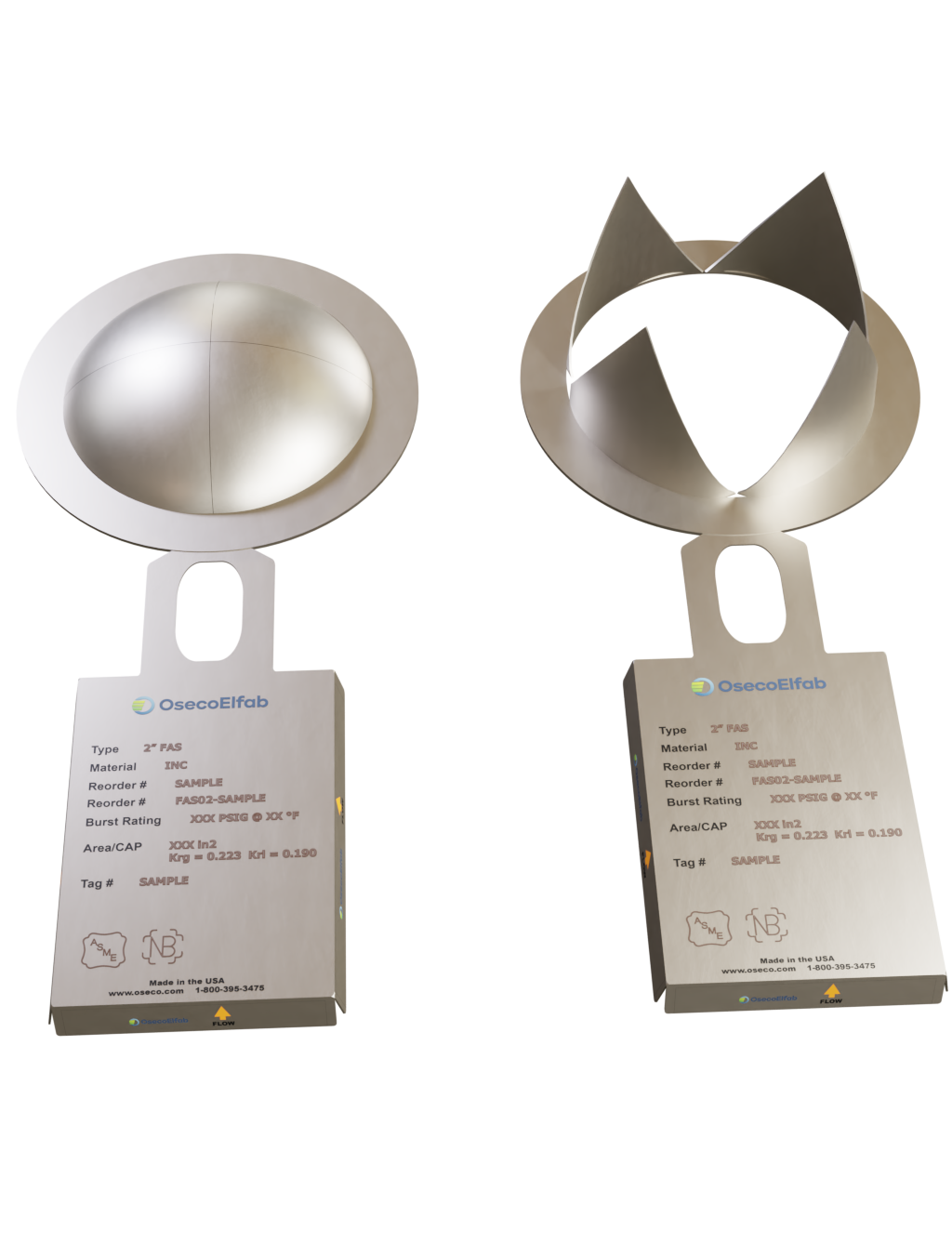

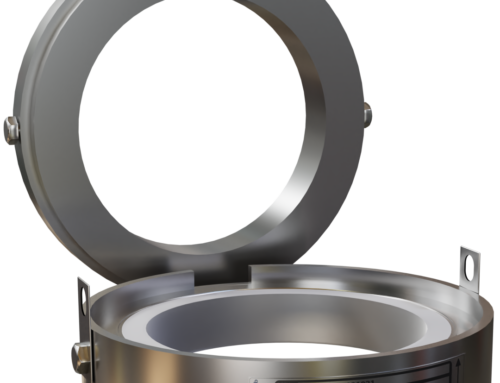

- The FAS is designed to pair with the FRDI insert holder, as well as the FRDI-P pretorqued insert holder, as well as the Safety Cartridge one-piece holder assembly.

- The MNFA for a 1″ FAS is 0.864 square inches

- The MNFA for a 1.5″ FAS is 2.036 square inches

- The MNFA for a 2″ FAS is 3.355 square inches

- The MNFA for a 3″ FAS is 7.393 square inches

- The MNFA for a 4″ FAS is 12.73 square inches

- The MNFA for a 5″ FAS is 28.89 square inches

- The MNFA for a 6″ FAS is 50 square inches

- The MNFA for a 10″ FAS is 78.9 square inches

- The MNFA for a 12″ FAS is 113.1 square inches

- The MNFA for a 14″ FAS is 137.9 square inches

- The MNFA for a 16″ FAS is 176.7 square inches

- The MNFA for a 18″ FAS is 233.7 square inches

- The MNFA for a 24″ FAS is 424.6 square inches

- For a 1” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 70 psig up to a maximum burst pressure of 5000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 1″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 110 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 220 psig. If the burst pressure is below 475 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 4100 psig.

- For a 1″ FAS made from Nickel 200, the minimum burst pressure possible is 70 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 140 psig. If the burst pressure is below 350 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 3500 psig.

- For a 1″ FAS made from Inconel 600, the minimum burst pressure possible is 100 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 200 psig. If the burst pressure is below 400 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 4000 psig.

- For a 1″ FAS made from Monel 400, the minimum burst pressure possible is 75 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 140 psig. If the burst pressure is below 350 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 3750 psig.

- For a 1″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 135 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 270 psig. If the burst pressure is below 550 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 5000 psig.

- For a 1.5” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 50 psig up to a maximum burst pressure of 4500 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 1.5″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 80 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 160 psig. If the burst pressure is below 350 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 4000 psig.

- For a 1.5″ FAS made from Nickel 200, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 100 psig. If the burst pressure is below 250 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2900 psig.

- For a 1.5″ FAS made from Inconel 600, the minimum burst pressure possible is 80 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 170 psig. If the burst pressure is below 300 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 3900 psig.

- For a 1.5″ FAS made from Monel 400, the minimum burst pressure possible is 60 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 120 psig. If the burst pressure is below 275 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 3500 psig.

- For a 1.5″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 125 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 250 psig. If the burst pressure is below 400 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 4500 psig.

- For a 2” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 40 psig up to a maximum burst pressure of 3500 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 2″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 60 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 120 psig. If the burst pressure is below 270 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 3000 psig.

- For a 2″ FAS made from Nickel 200, the minimum burst pressure possible is 40 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 80 psig. If the burst pressure is below 180 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2000 psig.

- For a 2″ FAS made from Inconel 600, the minimum burst pressure possible is 65 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 130 psig. If the burst pressure is below 225 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2500 psig.

- For a 2″ FAS made from Monel 400, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 100 psig. If the burst pressure is below 200 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2300 psig.

- For a 2″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 100 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 200 psig. If the burst pressure is below 300 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 3500 psig.

- For a 3” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 30 psig up to a maximum burst pressure of 2100 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 3″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 55 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 110 psig. If the burst pressure is below 200 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2000 psig.

- For a 3″ FAS made from Nickel 200, the minimum burst pressure possible is 30 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 60 psig. If the burst pressure is below 145 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1600 psig.

- For a 3″ FAS made from Inconel 600, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 100 psig. If the burst pressure is below 225 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2100 psig.

- For a 3″ FAS made from Monel 400, the minimum burst pressure possible is 40 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 80 psig. If the burst pressure is below 175 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1800 psig.

- For a 3″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 80 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 160 psig. If the burst pressure is below 250 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2000 psig.

- For a 4” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 40 psig up to a maximum burst pressure of 2000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 4″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 110 psig. If the burst pressure is below 200 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2000 psig.

- For a 4″ FAS made from Nickel 200, the minimum burst pressure possible is 40 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 80 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1400 psig.

- For a 4″ FAS made from Inconel 600, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 100 psig. If the burst pressure is below 175 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1800 psig.

- For a 4″ FAS made from Monel 400, the minimum burst pressure possible is 45 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 90 psig. If the burst pressure is below 150 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1600 psig.

- For a 4″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 70 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 140 psig. If the burst pressure is below 250 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2000 psig.

- For a 6” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 40 psig up to a maximum burst pressure of 2000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 6″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 100 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1800 psig.

- For a 6″ FAS made from Nickel 200, the minimum burst pressure possible is 40 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 80 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1200 psig.

- For a 6″ FAS made from Inconel 600, the minimum burst pressure possible is 55 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 110 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1600 psig.

- For a 6″ FAS made from Monel 400, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 100 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1400 psig.

- For a 6″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 80 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 160 psig. If the burst pressure is below 175 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 2000 psig.

- For a 8” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 40 psig up to a maximum burst pressure of 1800 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For an 8″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 55 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 110 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1800 psig.

- For an 8″ FAS made from Nickel 200, the minimum burst pressure possible is 40 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 80 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1100 psig.

- For an 8″ FAS made from Inconel 600, the minimum burst pressure possible is 60 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 120 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1300 psig.

- For an 8″ FAS made from Monel 400, the minimum burst pressure possible is 50 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 100 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1200 psig.

- For an 8″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 85 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 170 psig. If the burst pressure is below 175 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1600 psig.

- For a 10” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 40 psig up to a maximum burst pressure of 1500 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 10″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 65 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 130 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1500 psig.

- For a 10″ FAS made from Nickel 200, the minimum burst pressure possible is 40 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 80 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1000 psig.

- For a 10″ FAS made from Inconel 600, the minimum burst pressure possible is 65 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 130 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1200 psig.

- For a 10″ FAS made from Monel 400, the minimum burst pressure possible is 55 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 110 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1100 psig.

- For a 10″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 100 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 200 psig. If the burst pressure is below 175 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1300 psig.

- For a 12” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 40 psig up to a maximum burst pressure of 1300 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 12″ FAS made from 316 Stainless Steel, the minimum burst pressure possible is 75 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 150 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1500 psig.

- For a 12″ FAS made from Nickel 200, the minimum burst pressure possible is 40 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 80 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1000 psig.

- For a 12″ FAS made from Inconel 600, the minimum burst pressure possible is 75 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 150 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1100 psig.

- For a 12″ FAS made from Monel 400, the minimum burst pressure possible is 60 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 120 psig. If the burst pressure is below 125 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1000 psig.

- For a 12″ FAS made from Hastelloy C 276, the minimum burst pressure possible is 110 psig, but the minimum burst pressure that enables the FAS to withstand full vacuum is 220 psig. If the burst pressure is below 175 psig, the RFAS (an FAS with a stiffening ring) is recommended, to ensure the tag stays attached to the disk. The maximum burst pressure is 1300 psig.

- For a 14” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 45 psig up to a maximum burst pressure of 1000 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For a 16” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 50 psig up to a maximum burst pressure of 900 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- For an 18” FAS, the combined burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from 50 psig up to a maximum burst pressure of 800 psig. Each of the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) has its own, more limited range within those bounds.

- The FAS is not currently offered in a 20″ line size.

- The FAS is not currently offered in a 22″ line size.

- For a 24″ FAS, consult the factory for minimum and maximum burst pressures.