OsecoElfab’s VAPRO Rupture Disc

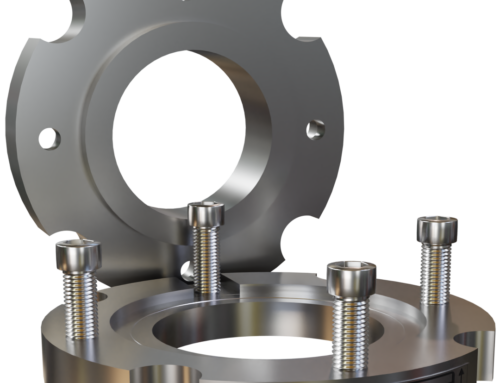

OsecoElfab’s bi-directional VAPRO discs are excellent for applications requiring both positive and vacuum pressure protection. The VAPRO is used in applications requiring extremely low vacuum relief. It can activate as low as 6″ Water Column (W.C.) vacuum. As vacuum within a vessel approaches the disc set pressure, a girdle is loaded until it collapses back past a knife blade assembly, opening the seal. Under positive pressure conditions, a perforated metal top section activates at a predetermined set point, just like a model CO rupture disk. The vacuum burst pressure range encompasses 6″ – 30″ (W.C.), with a positive burst pressure range of 4 psig to 150 psig. With sizes ranging from 3” to 10”, the VAPRO is ideal for applications that need an inexpensive, dual-setpoint pressure safety device. The VAPRO is considered a “composite” rupture disk because it always incorporates at least three distinct layers: a metal slotted top section (which controls the positive burst pressure), then a slit-slot Teflon cover layer (which separates the metal above from the seal below), then a solid fluoropolymer seal (a solid sheet which holds back the process fluid and prevents leakage). Finally, a flexible, stainless-steel girdle, which controls the vacuum set pressure is added to the bottom of the disk assembly. The VAPRO is designed for operation in applications where normal system pressures do not exceed 80% of the stamped burst pressure.

- The VAPRO is available in line sizes ranging from 3 inch diameter all the way up to 10 inches diameter.

- The VAPRO is available in vacuum burst pressures ranging from 6 inches water column all the way up to 30+ inches water column.

- The VAPRO is available in positive burst pressures ranging from 4 psig all the way up to 150 psig.

- The VAPRO is available in burst temperatures ranging from cryogenic temperatures all the way up to 400 degrees F.

- The VAPRO is available in all OE standard materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276). Other materials may be available or offered on request.

- The VAPRO works well in gas or vapor services, as well as liquid or two-phase services.

- The VAPRO is not ASME UD stamped. A default Kr value of 2.4 must be used when performing sizing calculations with this rupture disk.

- The VAPRO has an 80% operating ratio, meaning the VAPRO operates reliably and with a long service life at pressures up to 80% of the marked burst pressure. Pressure excursions above this 80% operating ratio will shorten the lifespan of the VAPRO.

- The VAPRO is offered with a standard 0% Manufacturing Design Range (MDR), meaning there will never be any variation between what burst pressure you order, and what burst pressure is marked on the tag of the rupture disk.

- The VAPRO uses a custom burst tolerance for the vacuum set pressure of + 6 inches water column of marked burst pressure. The VAPRO uses an ASME standard tolerance for positive set pressures of +/- 5% of marked burst pressure.

- The VAPRO is a non-scored metal rupture disk, with potential for fragmentation. This means the VAPRO, and composite rupture disks in general, cannot and should not be installed upstream from a pressure relief valve.

- The VAPRO is not offered with a vacuum support, as it is designed to burst at a specific vacuum rating.

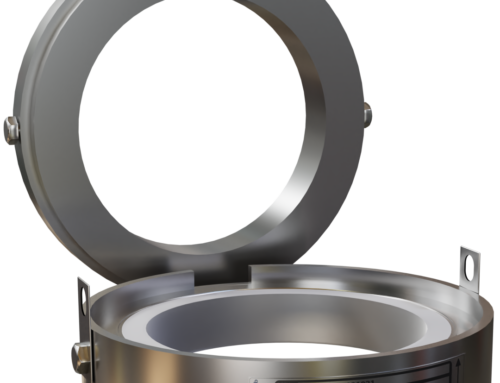

- The VAPRO is designed to be installed into the VRDI rupture disk holder.

- The VAPRO is both a forward acting metal rupture disk, and a Teflon reverse acting rupture disk. Positive process pressure is applied to the concave side of the rupture disk. Increasing process pressure stretches the metal center section of the rupture disk until the metal yields and tears open between the holes drilled into the disk. Vacuum process pressure sucks the Teflon seal down onto knife blades, welded into the VRDI holder, causing the Teflon seal to puncture and cut open along the knives.

- The VAPRO, like all forward acting, metal rupture disks, does best in static pressure applications. The VAPRO handles pressure cyclic services fairly well, but reverse acting metal rupture disks are typically recommended, to ensure the tag stays attached to the disk for services with oscillating pressures.

- The VAPRO is not designed, manufactured, nor certified to ASME BPVC Section XIII requirements.

- The factory must be consulted for MNFA values for the VAPRO rupture disk.

- For a 3” VAPRO, the vacuum burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from a minimum of 6 inches water column up to a maximum of 30 inches water column. The positive burst pressure ranges from a minimum of 11 psig up to a maximum burst pressure of 150 psig.

- For a 4” VAPRO, the vacuum burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from a minimum of 6 inches water column up to a maximum of 30 inches water column. The positive burst pressure ranges from a minimum of 8 psig up to a maximum burst pressure of 125 psig.

- For a 6” VAPRO, the vacuum burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from a minimum of 6 inches water column up to a maximum of 30 inches water column. The positive burst pressure ranges from a minimum of 6 psig up to a maximum burst pressure of 100 psig.

- For a 8” VAPRO, the vacuum burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from a minimum of 6 inches water column up to a maximum of 30 inches water column. The positive burst pressure ranges from a minimum of 5 psig up to a maximum burst pressure of 75 psig.

- For a 10” VAPRO, the vacuum burst pressure range for all the standard OE materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276) runs from a minimum of 6 inches water column up to a maximum of 30 inches water column. The positive burst pressure ranges from a minimum of 4 psig up to a maximum burst pressure of 50 psig.