OsecoElfab’s MV-RD Explosion Vents

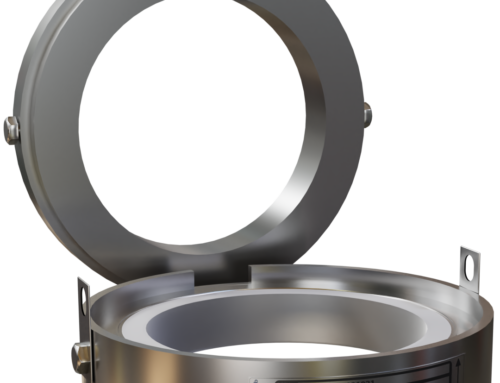

OsecoElfab’s MV-RD is ideal for bag houses, dust collectors bulk storage units requiring a rectangular vent. OsecoElfab’s MV-RD explosion vent is designed for high cycling applications such as dust collectors and bag houses, and for bulk storage units and ductwork applications requiring a rectangular vent. It may be exposed to system pressures up to 80% of the stamped burst pressure range and is suitable for applications that experience vacuum pressure up to 12psig/24.4 inHg. The MV-RD’s high cycling characteristics reduce maintenance and increase the vent’s life cycle. It mounts on enclosures where dust explosions may occur and will activate to safely relieve pressure in the event of a deflagration, thereby preventing a large explosion.

The MV family offers an industry-leading performance tolerance of +/- 0.25 psig. Each vent features design characteristics that reduce the maintenance required while offering a longer service life. All vents meet the requirements of the OHSA Combustible Dust National Emphasis Program and NFPA 68. A 10-day lead time is available for common sizes of MV-RD, MV-CD and MV-RF through our MV vent stocking program.

- The MV-RD is available in sizes ranging from 12”x12” all the way up to 36”x44”.

- The MV-RD is available in set pressures ranging from 1.5 psig up to 14 psig.

- The MV-RD has a set pressure tolerance of +/- 0.25 psig.

- The MV-RD is rated for temperatures ranging from -20 degrees F all the way up to 150 degrees F.

- The MV-RD has a 80% operating ratio, meaning the MV-RD operates reliably and with a long service life at pressures up to 80% of the marked burst pressure. Pressure excursions above this 80% operating ratio will shorten the lifespan of the MV-RD.

- The MV-RD is available with a 2 year warranty as a standard

- The MV-RD is available in all OE standard materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276). Other materials may be available or offered on request.

- The MV-RD utilizes a hinged opening design, ensuring it remains non-fragmenting.

- The MV-RD is capable of withstanding partial vacuum, at pressures down to -10 psig to -12 psig.

- The MV-RD is designed to meet all NFPA 61 and NFPA 68 requirements for explosion vents.

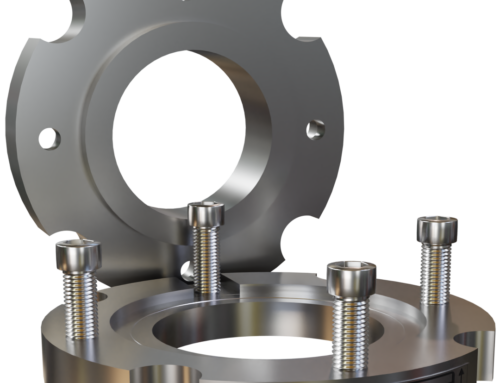

- The MV-RD can be paired with the SVT-03 sensor, to allow for remote monitoring of vent activation.

- For a 12”x12” MV-RD, the relief area is 129.0 square inches.

- For a 12”x24” MV-RD, the relief area is 264.0 square inches.

- For an 18”x24” MV-RD, the relief area is 405.0 square inches.

- For a 24”x24” MV-RD, the relief area is 546.0 square inches.

- For an 18”x36” MV-RD, the relief area is 595.0 square inches.

- For a 24”x36” MV-RD, the relief area is 825.0 square inches.

- For a 36”x36” MV-RD, the relief area is 1251.0 square inches.

- For a 36”x44” MV-RD, the relief area is 1533.0 square inches.

- For a 12”x12” MV-RD, the minimum set pressure is 2.5 psig, the maximum set pressure is 14.0 psig, and the maximum vacuum rating is -12.0psig.

- For a 12”x24” MV-RD, the minimum set pressure is 1.25 psig, the maximum set pressure is 8.0 psig, and the maximum vacuum rating is -12.0psig.

- For an 18”x24” MV-RD, the minimum set pressure is 1.25 psig, the maximum set pressure is 6.25 psig, and the maximum vacuum rating is -10.0psig.

- For a 24”x24” MV-RD, the minimum set pressure is 1.25 psig, the maximum set pressure is 4.25 psig, and the maximum vacuum rating is -12.0psig.

- For an 18”x36” MV-RD, the minimum set pressure is 1.5 psig, the maximum set pressure is 6.75 psig, and the maximum vacuum rating is -12.0psig.

- For a 24”x36” MV-RD, the minimum set pressure is 1.25 psig, the maximum set pressure is 4.25 psig, and the maximum vacuum rating is -12.0psig.

- For a 36”x36” MV-RD, the minimum set pressure is 1.25 psig, the maximum set pressure is 2.25 psig, and the maximum vacuum rating is -12.0psig.

- For a 36”x44” MV-RD, the minimum set pressure is 1 psig, the maximum set pressure is 2 psig, and the maximum vacuum rating is -10.0psig.