OsecoElfab’s PRO+KRGL Rupture Disc

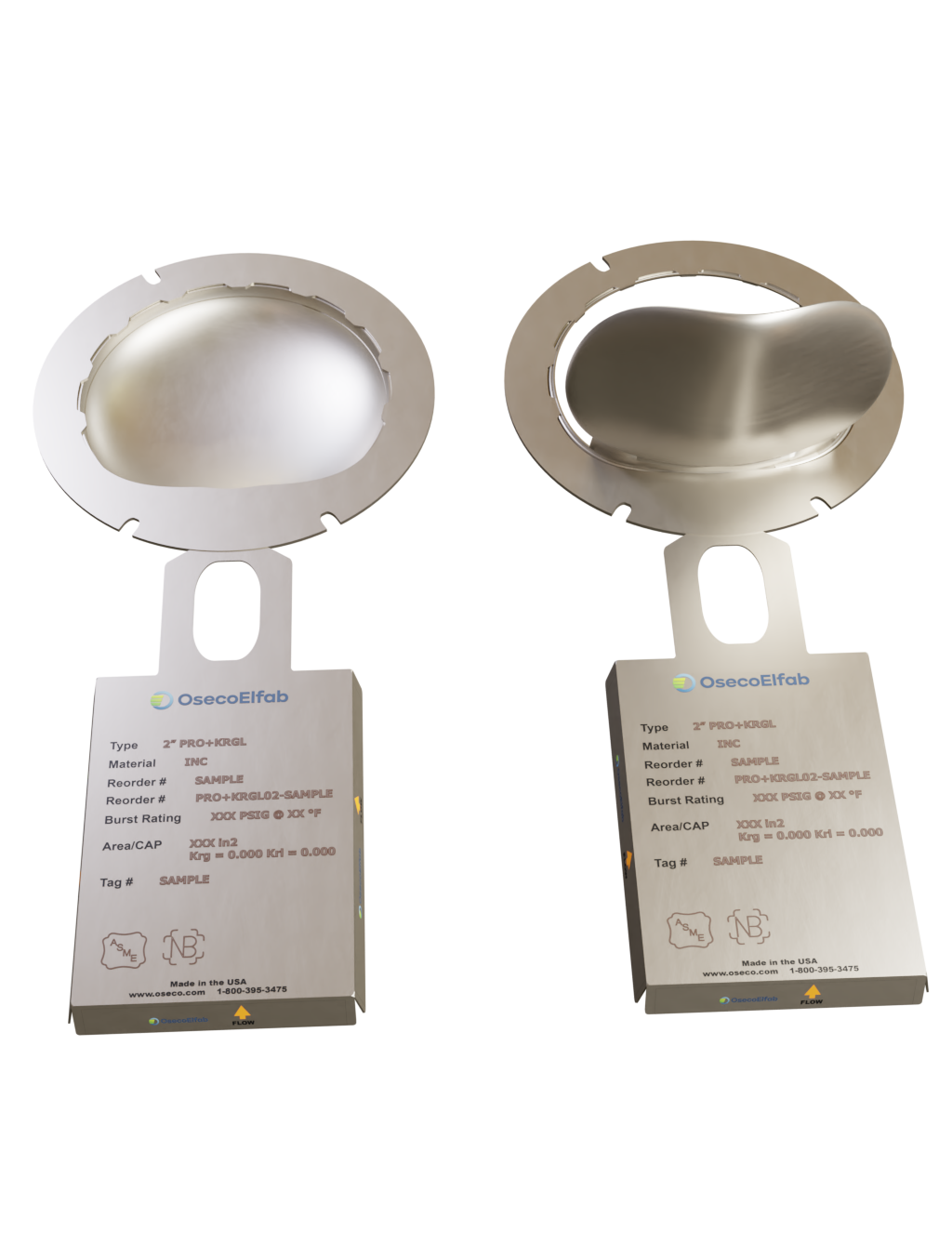

OsecoElfab manufactures the PRO+KRGL rupture disk, which is a high-performance, reverse acting rupture disc designed and manufactured for extremely demanding rupture disc applications. The PRO+ is designed and intended only for gas or vapor services, while the more versatile PRO+KRGL is designed for any fluid phase service. The PRO+ and the PRO+KRGL both features a very low Kr value, and was the first rupture disk marketed with a 95% operating ratio. The disc is circumference-scored after the forming of its low crown, and employs and outlet ring with teeth to ensure the rupture disk opens under any conditions. This process yields a high-performance disc able to withstand high operating pressures within the most difficult applications. The PRO+KRGL offers a smooth non-scored surface on the process side. This limits product accumulation on the disc and reduces the risk of polymerization and crystallization of media on the disc surface. The low KR value and high reliability make the PRO+KRGL an excellent choice for isolation of safety relief valves.

- The PRO+KRGL is available in line sizes 1.0”, 1.5”, 2.0”, 3.0”, 4.0”, 6.0”, 8.0”, and 10.0”.

- The PRO+KRGL is available in burst pressures ranging from 4 psig all the way up to 775 psig.

- The PRO+KRGL is available in burst temperatures ranging from cryogenic temperatures all the way up to 900 degrees F.

- The PRO+KRGL is available in all OE standard materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276). Other materials may be available or offered on request.

- The PRO+KRGL works well in gas or vapor services, as well as liquid or two-phase services.

- The Kr value for the PRO+KRGL, when opened by any fluid phase is Krgl = 0.69. OsecoElfab also offers a PRO+ variant with a gas-only Krg = 0.29.

- The PRO+KRGL has a 95% operating ratio, meaning the PRO+KRGL operates reliably and with a long service life at pressures up to 95% of the marked burst pressure. Pressure excursions above this 95% operating ratio will shorten the lifespan of the PRO+KRGL.

- The PRO+KRGL is only offered with a 0% Manufacturing Design Range (MDR), meaning there will never be any variation between what burst pressure you order, and what burst pressure is marked on the tag of the rupture disk.

- The PRO+KRGL maintains or exceeds the ASME-specified burst tolerances of +/- 5% of marked burst pressure for burst pressures above 40 psig, or +/- 2 psig for burst pressures at or below 40 psig.

- The PRO+KRGL is a scored metal rupture disk, with a non-fragmenting design, meaning the PRO+KRGL can be installed upstream from a pressure relief valve.

- The PRO+KRGL does not have a vacuum support. The PRO+KRGL is designed to handle vacuum services without any additional design enhancements.

- The PRO+KRGL is a reverse acting metal rupture disk. Process pressure is applied to the convex side of the rupture disk. Increasing process pressure collapses the dome of the rupture disk until the dome inverts, and the metal yields and tears open along the scored lines.

- The PRO+KRGL, like all reverse acting metal rupture disks, does best in static pressure applications, but also handles pressure cyclic services extraordinarily well. The PRO+KRGL has been tested in excess of 1,000,000 full scale pressure cycles (0 psig to 95% of marked burst pressure and back down to 0 psig again), with no evidence of fatigue induced failure or alteration of burst pressure.

- The PRO+KRGL is offered with a PFA liner or shield on the inlet side of the rupture disk, to enhance corrosion protection. This configuration is called the PRO+KRGL-L

- The PRO+KRGL is designed, manufactured, and certified to ASME BPVC Section XIII requirements.

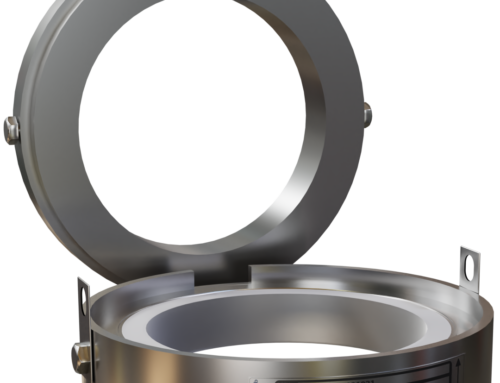

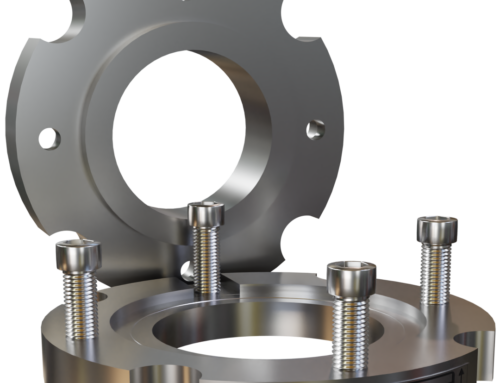

- The PRO+KRGL is designed to pair with the PRDI insert holder, as well as the PRDI-P pretorqued insert holder.

- The MNFA for a 1.0″ PRO+KRGL is 0.864 square inches

- The MNFA for a 1.5″ PRO+KRGL is 2.036 square inches

- The MNFA for a 2.0″ PRO+KRGL is 3.355 square inches

- The MNFA for a 3.0″ PRO+KRGL is 7.393 square inches

- The MNFA for a 4.0″ PRO+KRGL is 12.73 square inches

- The MNFA for a 5.0″ PRO+KRGL is 28.89 square inches

- The MNFA for a 6.0″ PRO+KRGL is 50.0 square inches

- The MNFA for a 10.0″ PRO+KRGL is 78.9 square inches

- For a 1.0” PRO+KRGL, the minimum burst pressure is 21 psig. The maximum burst pressure is 400 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 775 psig.

- For a 1.5” PRO+KRGL, the minimum burst pressure is 14 psig. The maximum burst pressure is 400 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 775 psig.

- For a 2.0” PRO+KRGL, the minimum burst pressure is 8 psig. The maximum burst pressure is 300 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 775 psig.

- For a 3.0” PRO+KRGL, the minimum burst pressure is 8 psig. The maximum burst pressure is 200 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 725 psig.

- For a 4.0” PRO+KRGL, the minimum burst pressure is 8 psig. The maximum burst pressure is 200 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 400 psig.

- For a 6.0” PRO+KRGL, the minimum burst pressure is 6 psig. The maximum burst pressure is 100 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 300 psig.

- For a 8.0” PRO+KRGL, the minimum burst pressure is 6 psig. The maximum burst pressure is 25 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 250 psig.

- For a 10.0” PRO+KRGL, the minimum burst pressure is 4 psig. The maximum burst pressure is 15 psig but, if fragmentation is allowable, the maximum burst pressure can be extended to 100 psig.