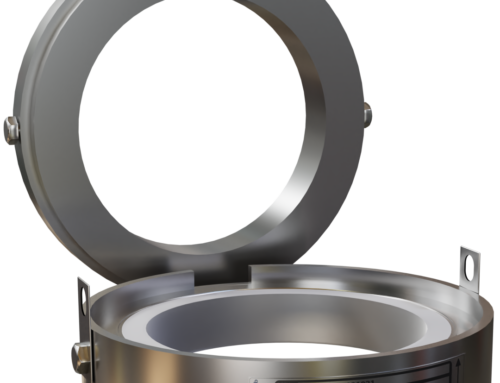

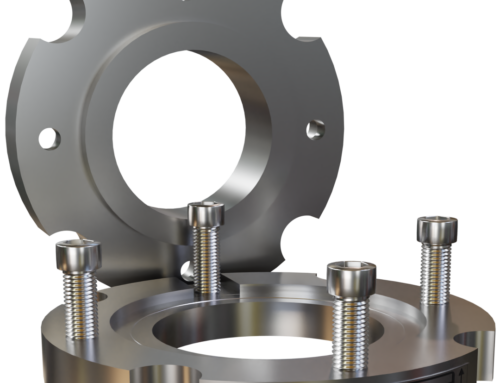

OsecoElfab’s RDI Rupture Disc Holder

The OsecoElfab RDI Insert Rupture Disc Holder is a reduced diameter, flat-faced flange assembly that bolts between standard ANSI pipe flanges and fits within the bolt circle. The RDI has 30° beveled seat and uses this angular sealing surface to create a metal-to-metal “bite” seal between the RDI inlet, and the rupture disk inlet seat surface. This holder allows the rupture disc to be preassembled to ensure it is properly seated before installation into the pressure systems. RDI Insert Holders are available in standard ANSI flange ratings up to 42″ and are offered in three overall height arrangements.

- The RDI is for use with the STD and CO rupture disks.

- The RDI is compatible with the AMS, SVT, and LPSF burst disk indicator sensors.

- The RDI is available in line sizes ranging from 1 inch diameter all the way up to 42 inches diameter.

- The RDI is compatible with service temperatures ranging from cryogenic temperatures all the way up to 900 degrees F.

- The RDI is available in all OE standard materials (316 Stainless Steel, Nickel 200, Inconel 600, Monel 400, and Hastelloy C 276). Other materials may be available or offered on request. The inlet ring material can be specified as a different material than the outlet ring material.

- The RDI works well in gas or vapor services, as well as liquid or two-phase services.

- The RDI may work well in sticky or fouling services, although alternative holder designs such as the TopHat Assembly are recommended in such environments.

- The RDI is highly torque sensitive. Torque instructions, particularly maintaining even torque during installation are critical for proper rupture disk performance within this holder assembly.

- The RDI is available in ANSI 150#, ANSI 300#, ANSI 600#, ANSI 900#, ANSI 1500#, and ANSI 2500# Flange Classes

- The RDI is available in Raised Face, Flat Face, Crush Ring, and RTJ flange facing arrangements.

- The RDI can be tapped for instrumentation on both the inlet and outlet rings.

- The RDI can be offered as a double disk assembly, allowing for the installation of two rupture disks in series.

- Kr values are specific to the rupture disk model used. As such, the RDI does not have its own, unique Kr value.

- Operating Ratios are specific to the rupture disk model used. As such, the RDI does not have its own, unique operating ratio.

- Manufacturing Ranges are specific to the rupture disk model used. As such, the RDI does not have its own, unique manufacturing range.

- Burst Tolerances are specific to the rupture disk model used. As such, the RDI does not have its own, unique burst tolerance.

- Fragmentation is specific to the rupture disk model used. As such, the RDI is neither fragmenting nor non-fragmenting.

- A 1” RDI has a standard overall height of 1.62”. Custom height RDI’s are available upon request.

- A 1.5” RDI has a standard overall height of 1.62”. Custom height RDI’s are available upon request.

- A 2” RDI has a standard overall height of 1.75”. Custom height RDI’s are available upon request.

- A 3” RDI has a standard overall height of 1.75”. Custom height RDI’s are available upon request.

- A 4” RDI has a standard overall height of 1.75”. Custom height RDI’s are available upon request.

- A 6” RDI has a standard overall height of 2.25”. Custom height RDI’s are available upon request.

- An 8” RDI has a standard overall height of 2.31”. Custom height RDI’s are available upon request.

- A 10” RDI has a standard overall height of 2.43”. Custom height RDI’s are available upon request.

- A 12” RDI has a standard overall height of 2.62”. Custom height RDI’s are available upon request.

- The factory should be consulted for the overall height of any RDI above a 12” line size.