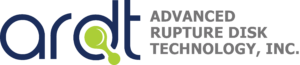

OsecoElfab’s Safety Cartridge Assembly

An innovative rupture disc solution to eliminate leaks, eliminate installation errors and increase safety. The Oseco Safety Cartridge combines the traditional three components of a rupture disc system into one hermetically sealed component. These high performance, one-piece units come leak-tight from the factory and install in minutes. No other rupture disc solution installs as reliably or easily as the Oseco Safety Cartridge. It guarantees leak protection by incorporating an electron beam weld design that completely removes the need to seal your rupture disc within a holder. This patented design makes the Oseco Safety Cartridge the only widely available solution to eliminate exterior seam leakage.

• The Safety Cartridge is available in line sizes 1.0″, 1.5″, 2.0″, 3.0″, 4.0″, 6.0″, 8.0″, 10.0″, and 12.0″.

• The Safety Cartridge is available in burst pressures ranging from 10 psig all the way up to 2000 psig. The available range shits based on line size and which rupture disk model is integrated into the Safety Cartridge assembly.

• The Safety Cartridge is available in burst temperatures ranging from cryogenic temperatures all the way up to 900 degrees F.

• The Safety Cartridge is available in most OE standard materials (316 Stainless Steel, Inconel 600, Monel 400, and Hastelloy C 276). Nickel 200 and Tantalum are not available for use in the Safety Cartridge assembly. Other materials may be available or offered on request.

• The Safety Cartridge works well in gas or vapor services, as well as liquid or two-phase services. The Safety Cartridge works particularly well in sticky or fouling services.

• The Safety Cartridge incorporates your choice of four of OsecoElfab’s most popular rupture disk models, the FAS, the OPR+, the OPK+, and the PCR.

• The Kr value for the Safety Cartridge varies by which model of OsecoElfab rupture disk is used. For the FAS option, when opened by vapors or gases the Krg = 0.223, and when opened by liquids or slurries the Krl = 0.19. For the PCR option, the Krg = 2.17. For the OPR+ option, the Krgl = 0.78, and for the OPK+ option, the Krgl = 1.5.

• The Safety Cartridge has a 90 – 95% operating ratio, depending on which rupture disk model is used, meaning the Safety Cartridge operates reliably and with a long service life at pressures up to 90% or 95% of the marked burst pressure. Pressure excursions above this 90% – 95% operating ratio will shorten the lifespan of the Safety Cartridge.

• The Safety Cartridge is only offered with a 0% Manufacturing Design Range (MDR), meaning there will never be any variation between what burst pressure you order, and what burst pressure is marked on the tag of the rupture disk.

• The Safety Cartridge maintains or exceeds the ASME-specified burst tolerances of +/- 5% of marked burst pressure for burst pressures above 40 psig, or +/- 2 psig for burst pressures at or below 40 psig.

• The Safety Cartridge utilizes only scored metal rupture disks with a non-fragmenting design, meaning the Safety Cartridge can be installed upstream from a pressure relief valve.

• The Safety Cartridge does not have a vacuum support. The Safety Cartridge is designed to handle vacuum services without any additional design enhancements.

• The Safety Cartridge integrated with the FAS is a forward acting metal rupture disk. Process pressure is applied to the concave side of the rupture disk. Increasing process pressure stretches the rupture disk until the metal yields and tears open along the scored lines. All other disk models integrated into the Safety Cartridge are reverse acting metal rupture disks. Process pressure is applied to the convex side of reverse acting rupture disks. Increasing process pressure collapses the dome of the rupture disk until the dome inverts, and the metal yields and tears open along the scored lines.

• The Safety Cartridge, like all rupture disks, does best in static pressure applications, but the Safety Cartridge also handles pressure cyclic services extraordinarily well. The OPR/OPK/PCR integrations have been tested in excess of 1,000,000 full scale pressure cycles (0 psig to 95% of marked burst pressure and back down to 0 psig again), with no evidence of fatigue induced failure or alteration of burst pressure.

• The Safety Cartridge is designed, manufactured, and certified to ASME BPVC Section XIII requirements.

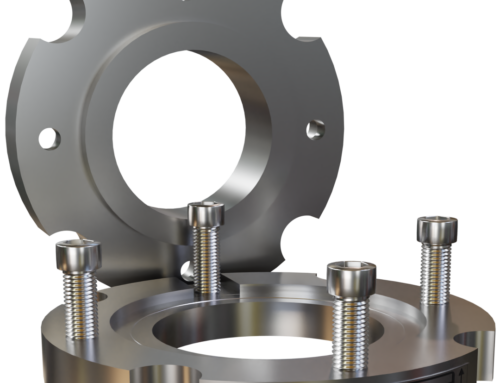

• The Safety Cartridge is a fully integrated rupture disk device. It needs no separate holder assembly, because it IS a holder assembly with a disk integrated into it.

• The Safety Cartridge does not leak. Every Safety Cartridge is leak checked to 1×10-8 cc-atm/sec using helium.

• The Safety Cartridge can be tapped on the downstream side of the rupture disk, to enable the use of a tell-tale assembly, or other suitable means of detecting pressure on the downstream side of the Safety Cartridge. 1/4″ NPT taps are standard, with socket weld options and 1/2″ tap options also available.

• The Safety Cartridge is designed for use within ASME and ANSI raised face or flat face flanges. The welded design of the Safety Cartridge prohibits its use in RTJ or crush ring flanged assemblies, as well as any threaded pipe union applications.

• The Safety Cartridge is available in ANSI flange class 150#, 300#, 600#, and 900# pressure ratings.

• The MNFA for a 1″ FAS Safety Cartridge is 0.864 square inches and, for a 1” OPR+ Safety Cartridge the MNFA is 0.78 square inches and, for a 1” OPK+ Safety Cartridge the MNFA is 0.79 square inches and, for a 1” PCR Safety Cartridge the MNFA is 0.6 square inches.

• The MNFA for a 1.5″ FAS Safety Cartridge is 2.036 square inches and, for a 1.5” OPR+ Safety Cartridge the MNFA is 1.69 square inches and, for a 1.5” OPK+ Safety Cartridge the MNFA is 1.71 square inches and, for a 1.5” PCR Safety Cartridge the MNFA is 1.3 square inches.

• The MNFA for a 2″ FAS Safety Cartridge is 3.355 square inches and, for a 2” OPR+ Safety Cartridge the MNFA is 2.84 square inches and, for a 2” OPK+ Safety Cartridge the MNFA is 2.90 square inches and, for a 2” PCR Safety Cartridge the MNFA is 2.5 square inches.

• The MNFA for a 3″ FAS Safety Cartridge is 7.393 square inches and, for a 3” OPR+ Safety Cartridge the MNFA is 6.81 square inches and, for a 3” OPK+ Safety Cartridge the MNFA is 7.03 square inches and, for a 3” PCR Safety Cartridge the MNFA is 4.8 square inches.

• The MNFA for a 4″ FAS Safety Cartridge is 12.73 square inches and, for a 4” OPR+ Safety Cartridge the MNFA is 10.96 square inches and, for a 4” OPK+ Safety Cartridge the MNFA is 11.17 square inches and, for a 4” PCR Safety Cartridge the MNFA is 8.0 square inches.

• The MNFA for a 6″ FAS Safety Cartridge is 28.89 square inches and, for a 6” OPR+ Safety Cartridge the MNFA is 23.38 square inches and, for a 6” OPK+ Safety Cartridge the MNFA is 24.18 square inches and, for a 6” PCR Safety Cartridge the MNFA is 18 square inches.

• The MNFA for an 8″ FAS Safety Cartridge is 50.0 square inches and, for an 8” OPR+ Safety Cartridge the MNFA is 44.18 square inches and, for an 8” OPK+ Safety Cartridge the MNFA is 45.46 square inches and, for an 8” PCR Safety Cartridge the MNFA is 32 square inches.

• The MNFA for a 10” OPR+ Safety Cartridge is 65.05 square inches and, for a 10” OPK+ Safety Cartridge the MNFA is 67.64 square inches and, for a 10” PCR Safety Cartridge the MNFA is 51.25 square inches.

• The MNFA for a 12” OPR+ Safety Cartridge is 94.86 square inches and, for a 12” OPK+ Safety Cartridge the MNFA is 99.29 square inches.

• For a 1.0” Safety Cartridge, the minimum available burst pressure is 100 psig, and the maximum available burst pressure is 2000 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For a 1.5” Safety Cartridge, the minimum available burst pressure is 50 psig, and the maximum available burst pressure is 2000 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For a 2.0” Safety Cartridge, the minimum available burst pressure is 25 psig, and the maximum available burst pressure is 1500 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For a 3.0” Safety Cartridge, the minimum available burst pressure is 15 psig, and the maximum available burst pressure is 1500 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For a 4.0” Safety Cartridge, the minimum available burst pressure is 10 psig, and the maximum available burst pressure is 1200 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For a 6.0” Safety Cartridge, the minimum available burst pressure is 13 psig, and the maximum available burst pressure is 1000 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For an 8.0” Safety Cartridge, the minimum available burst pressure is 13 psig, and the maximum available burst pressure is 700 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For a 10.0” Safety Cartridge, the minimum available burst pressure is 13 psig, and the maximum available burst pressure is 274 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.

• For a 12.0” Safety Cartridge, the minimum available burst pressure is 13 psig, and the maximum available burst pressure is 250 psig. Each available disk model covers some portion of that range, and the data sheet should be checked to ensure your selected model offers your required burst pressure.